About the Department

Profile

Petro Chemical Technology is a specialized branch of chemical engineering which deals with operation of refining and Petrochemical Technology. The term Petrochemical refers to the organic chemicals which are obtained directly or indirectly from crude Petroleum. It is the downstream sector of petroleum consist activities such as the refining, marketing and distribution of petroleum products. Refining process is crucial for an oil product such as then only it can be used. Petrochemicals mainly have needs in refining, Petrochemical plants as well as downstream Petroleum industries and R&D organizations. The core subjects of petrochemical technology are reaction engineering, heat transfer, Mass transfer, fluid dynamics, Thermodynamics & Transport phenomena etc. The Petro chemical Technology can work as Petroleum Geologists, Reservoir Engineers, Production Engineers, and Drilling Engineer among several other profiles. The major Indian companies in this sector are, Reliance industries limited, gas authority of India limited, Indian petro chemical corporation limited, Geo Enpro Petroleum Ltd, Geometric Ltd, Indo rama Synthetics Limited, shell Technology limited, Grasim industries limited and Essor oil etc. In the present scenario the scope of petrochemical industry is very good as the government regulations are aligned with the industry and is playing an important part. The regulations have opened the market which is full of scope for the rapid growth of the industry and in turn, the growth of the economy.

Vision

To provide world class education in Petrochemical Technology, fostering expertise and innovation to meet evolving needs of the industry and society.

Mission

Program Educational Objectives (PEOs)

Bachelor of Petrochemical Technology curriculum is designed to prepare the graduates are having to:

Program Outcomes (POs)

Program Specific Outcomes (PSOs):

Lab Facilities

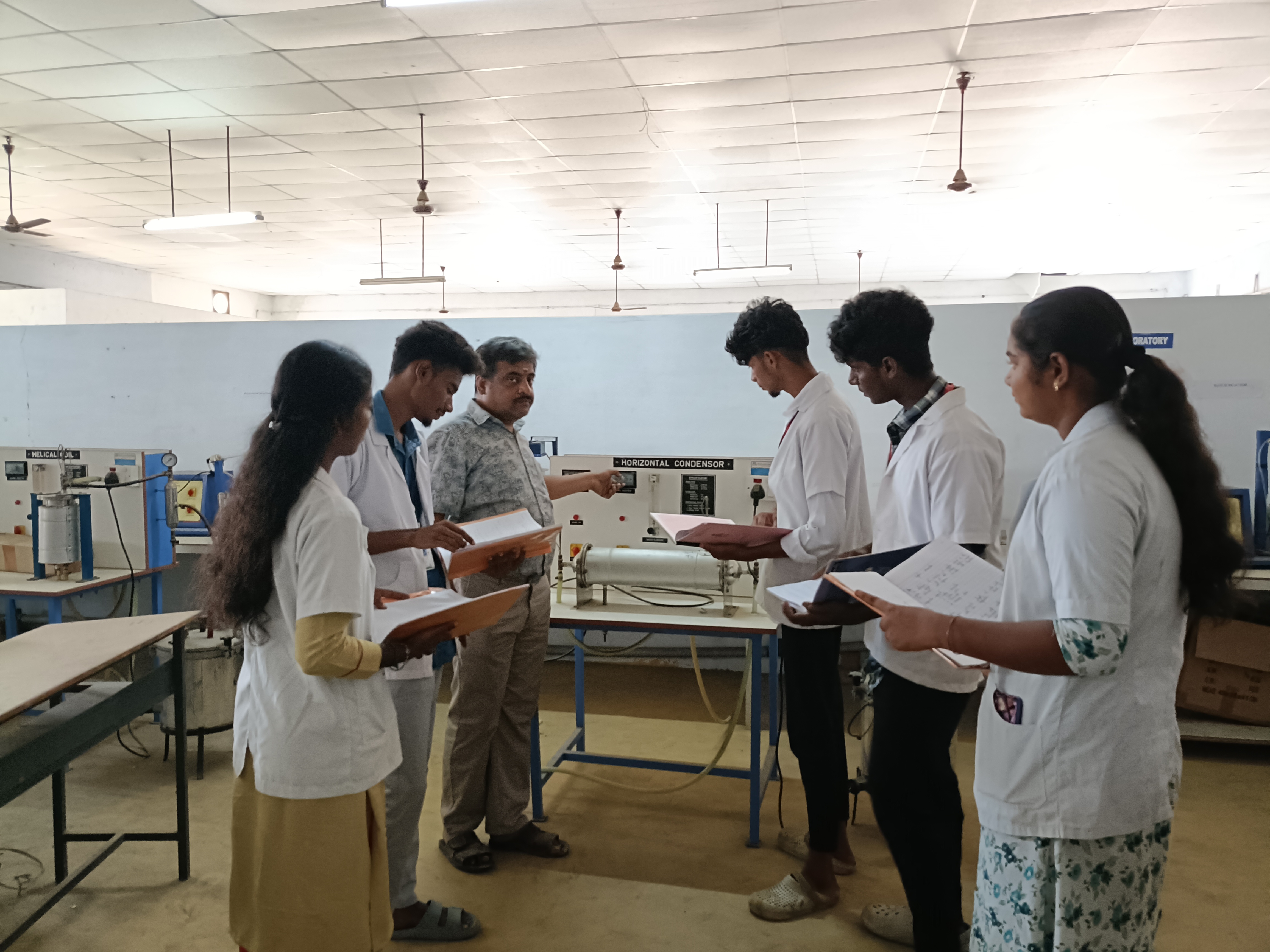

Heat Transfer Laboratory

A Heat Transfer Laboratory focuses on the study and practical applications of heat transfer principles, including conduction, convection and radiation. It allows students and researchers to experiment with various methods of heat exchange in different materials and system. Common equipment includes heat exchangers, thermal conductivity tester, and flow visualization setups. Experiments conducted in the lab help understand temperature gradients, heat flux and thermal resistance in real world applications such as HVAC systems, engines and manufacturing processes. The lab enhances learning through hands-on experimentation, fostering a deeper understanding of thermal energy movement and its impact on engineering designs.

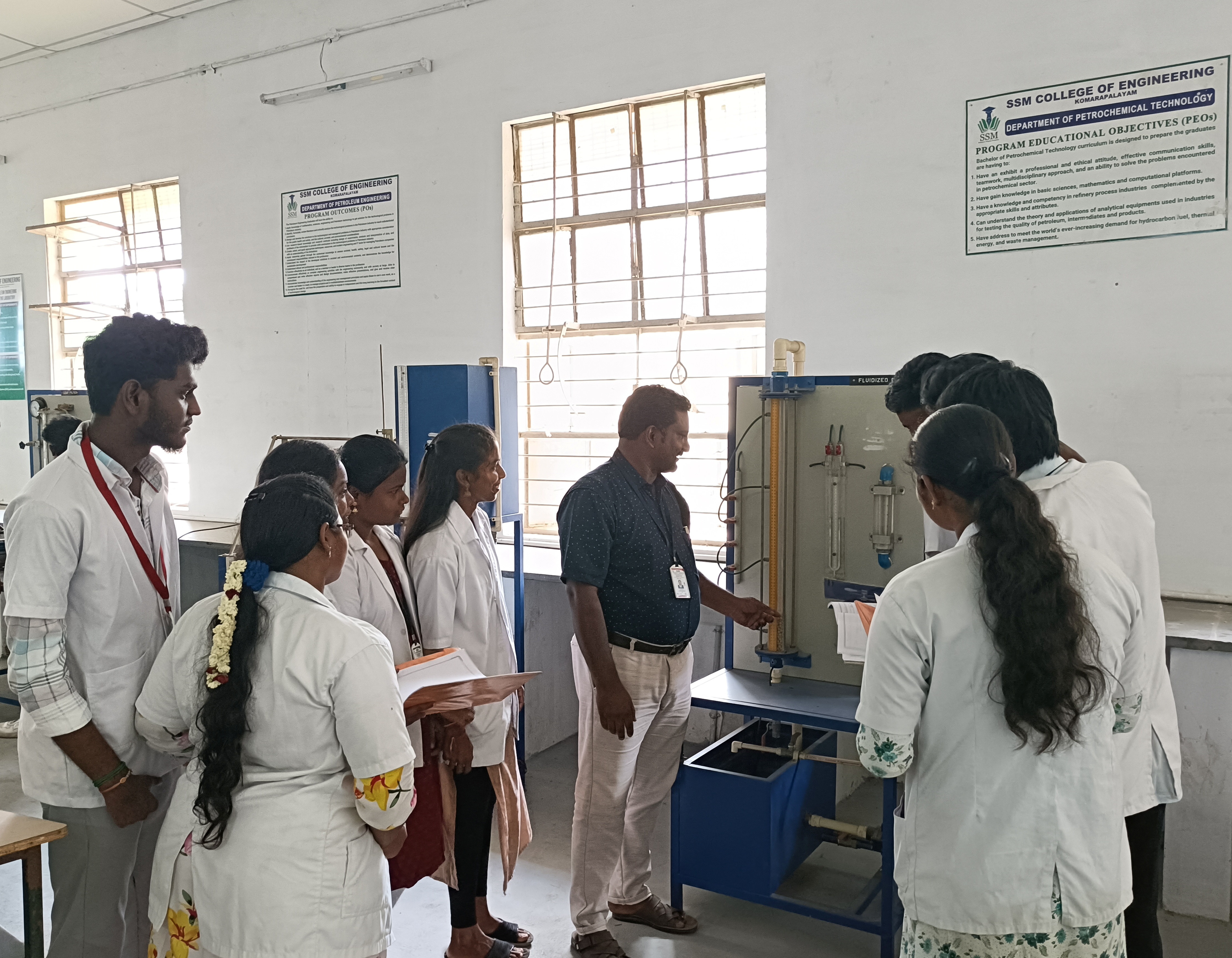

Fluid Mechanics and Solid Operation Laboratory

A Fluid Mechanics and Solid Operations Laboratory is a specialized facility for studying the behavior of fluids and solid materials under various conditions. It plays a crucial role in understanding material properties and fluid dynamics, which is essential in engineering, construction and environmental science. These labs provide hands on learning for students, bridging theory with real-world applications and advancing knowledge in fluid dynamics and solid operations.

Petrochemical and Polymer Analysis Laboratory

The Petrochemical and Polymer Analysis Laboratory provides students with hands-on experience in analyzing the chemical properties and behaviors of petrochemical products and polymers. Students learn to use advanced analytical instruments, such as chromatographs, spectrometers, and rheometers, to characterize materials, determine molecular structures, and evaluate polymer properties like viscosity and tensile strength. Through experiments, students gain insights into the processes involved in polymerization, petrochemical production, and the quality control of polymer-based products.

Petroleum Product Testing Laboratory

A Petroleum Product Testing Laboratory plays a crucial role in evaluating the quality, safety, and performance of various petroleum products such as gasoline, diesel, lubricants, and jet fuel. Students in this field learn to use advanced equipment like gas chromatographs and flashpoint testers to assess characteristics such as viscosity, density, sulfur content, and octane rating. They gain hands-on experience in analyzing product composition, ensuring compliance with industry standards and environmental regulations.

Mass Transfer Laboratory

A Mass Transfer Laboratory is essential for students studying chemical engineering and related fields. In this lab, students explore the principles of mass transfer, which involves the movement of molecules between different phases, such as gas, liquid, and solid. They conduct experiments involving diffusion, absorption, distillation, and filtration, using equipment like packed columns, membrane reactors, and separators. Through hands-on practice, students learn to analyze mass transfer rates and optimize processes in industries like petrochemical, pharmaceuticals, and food processing.

Chemical Reaction and Process Control Laboratory

The Chemical Reaction and Process Control Laboratory provides students with practical experience in understanding and optimizing chemical reactions and industrial processes. In this lab, students study reaction kinetics, reactor design, and control systems that regulate processes in industries like petrochemicals, pharmaceuticals, and food production. Using various reactors and control systems, they experiment with reaction rates, equilibrium, and temperature, pressure, and flow control. Students learn to apply mathematical models to predict reaction behavior and design automated systems that ensure safety, efficiency, and product quality.

Computational Petrochemical Laboratory

The Computational Petrochemical Laboratory is an essential learning environment for students studying chemical engineering, focusing on the simulation and modeling of petrochemical processes. In this lab, students use specialized software to simulate processes like refining, distillation, and chemical reactions, allowing them to analyze and optimize industrial systems. They learn to solve complex equations related to heat and mass transfer, thermodynamics, and fluid dynamics. The lab experience helps students understand how to predict performance, improve efficiency, and reduce environmental impact in petrochemical operations. Through computational tools, students gain insights into real-world challenges, enhancing their problem-solving and decision-making abilities in the industry.

Heat Transfer Laboratory

| S.No | Major Equipments |

| 1 | Double pipe Heat exchanger |

| 2 | Shell and Tube Heat Exchanger |

| 3 | Bare and Finned Tube Heat Exchanger |

| 4 | Composite wall setup |

| 5 | Stefan Boltzman apparatus |

| 6 | Emissivity measurement setup |

| 7 | Single effect evaporator or Multiple effect evaporator |

| 8 | Open pan evaporator |

| 9 | Boiler |

| 10 | Packed bed |

| 11 | Vertical condenser and Horizontal condenser |

| 12 | Helical coil |

| 13 | Jacketed vessel |

| 14 | Agitated vessel |

Fluid Mechanics and Solid Operations

| S.No | Major Equipments |

| 1 | Sieve shaker |

| 2 | Leaf filter |

| 3 | Plate and Frame Filter press |

| 4 | Batch Sedimentation |

| 5 | Jaw Crusher |

| 6 | Ball mill |

| 7 | Roll Crusher |

| 8 | Drop weight crusher |

| 9 | Drag on experiment setup |

| 10 | Centrifugal pump |

| 11 | Packed column |

Petrochemical and Polymer Analysis Laboratory

| S.No | Major Equipments |

| 1 | Refractometer |

| 2 | Cleveland Open cup Flash and fire point apparatus |

| 3 | Pensky Martien Flash and fire point apparatus |

| 4 | Redwood Viscometer |

| 5 | Saybolt Viscometer |

| 6 | KF-Titrator |

| 7 | Rotary vacuum evaporator. |

| 8 | UV- Visible spectrophotometer/FTIR. |

| 9 | Orsat apparatus/ Digital flue gas analyzer |

| 10 | Durometer |

| 11 | Melting point apparatus |

Petroleum Product Testing Laboratory

| S.No | Major Equipments |

| 1 | Hydrometer |

| 2 | Conradson Apparatus / Muffle furnace |

| 3 | Brook Field viscometer |

| 4 | Dean and Stark apparatus |

| 5 | ASTM Distillation apparatus |

| 6 | Aniline point apparatus |

| 7 | Copper corrosion apparatus |

| 8 | Cloud and Pour point apparatus |

| 9 | Smoke point apparatus |

| 10 | Reid -Vapour pressure apparatus |

| 11 | Centrifuge apparatus |

| 12 | Drop point apparatus |

| 13 | Ring and ball softening point apparatus |

| 14 | Ductilometer |

| 15 | Penetrometer |

Mass Transfer Laboratory

| S.No | Major Equipments |

| 1 | Simple distillation setup |

| 2 | Steam distillation setup |

| 3 | Packed column |

| 4 | Liquid-liquid extractor |

| 5 | Forced draft dryer |

| 6 | Wetted wall column |

| 7 | Rotating disc contactor |

| 8 | Cooling tower |

| 9 | Absorption column |

| 10 | Diffusion Cell |

| 11 | Surface Evaporation setup |

Mass Transfer Laboratory

| S.No | Major Equipments |

| 1 | Batch Reactor 1 |

| 2 | Plug flow reactor 1 |

| 3 | CSTR 1 |

| 4 | Sono-chemical reactor 1 |

| 5 | Packed bed reactor 1 |

| 6 | PFR followedbya CSTR |

| 7 | U tube Manometer with Controller 1 |

| 8 | Interacting / Non Interacting Tank 1 |

| 9 | Open loop Control System 1 |

| 10 | Closed loop Control System 1 |

| 11 | Control Valve Characteristics |

Major Equipments

| S.No | Major Equipments |

| 1 | Bare and Finned Tube Heat Exchanger |

| 2 | Open Pan Evaporator |

| 3 | Packed Bed |

| 4 | Sieve shaker |

| 5 | Jaw Crusher |

| 6 | Leaf filter |

| 7 | CSTR |

| 8 | Bomb calorimeter |

Renowned Alumni

Batch : 2015 - 2019

Organization : MProject Manager, Norway

Batch : 2015 – 2019

Organization : Drilling Engineer in ADNOC Group Dubai

Batch : 2017 - 2021

Organization : Drilling Engineer in ADNOC Group Dubai

Batch : 2018 - 2022

Organization : Assistant Engineer, Sakthi Sugars Limited,Erode

Value Added Programs

Workshops / Conferences / Seminars / Symposium

Industrial Visits & In-plant Training

| S.No | Companies |

| 1 | Chennai Petroleum Corporation Ltd, Chennai.(CPCL) |

| 2 | Cochin Refinery Ltd (CRL),cochin |

| 3 | Kothari Petrochemicals Limited, Chennai |

| 4 | Sakthi sugar Limited, Erode |

| 5 | Oil and Natural gas Corporation Ltd, Cauvery basin, Karaikal(ONGC) |

| 6 | DOW chemicals Ltd, Tuticorin |

| 7 | The India Cements Ltd, Sankagiri. |

| 8 | Fertilizer and chemicals Limited , cochin.(FACT) |

MoU with Companies

© 2025 | SSM College of Engineering, All Rights Reserved.